Clothing is very important to almost everyone around the world. There are different types of clothing, material, and even styles. Do you ever wonder about how these materials are made?

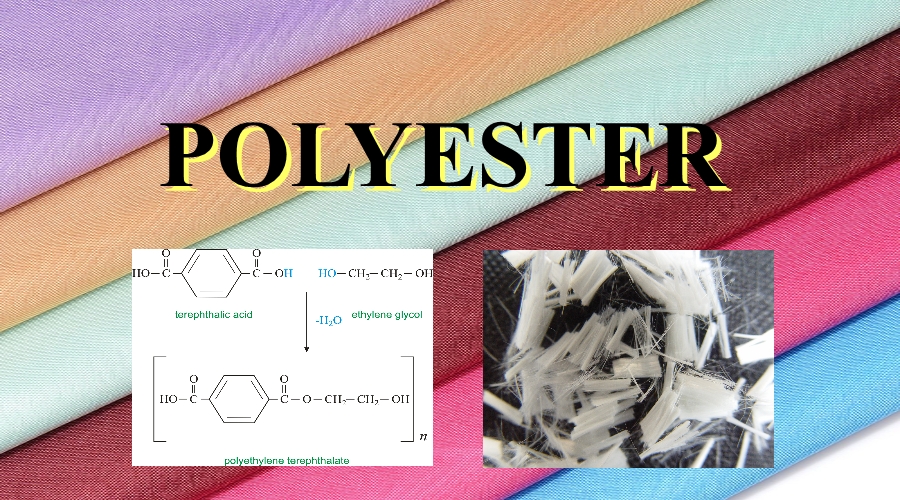

One of the most common materials out there is polyester fleece. Polyester is a synthetic fabric developed by British chemists in the 19th century, made using a chemical reaction involving terephthalic acid. This cloth is more durable than wool. There are three steps in making polyester.

- Condensation polymerization

- Melt spinning

- Drawing

Condensation polymerization occurs when terephthalic acid and alcohol chemically react in a vacuum at high temperatures. Then, the material is pressed out into a casting through as strips of ribbon. The ribbon then cools, hardens, and is cut into chips.

Melt spinning is when the dried chips are melted to about 260 degrees Celsius and extruded through spinnerets. The heated chips harden into fibers while coming out of spinnerets. Then, they are loosely wrapped around hot spools. Then, a thick rope forms from the fibers.

The last step is drawing. This is where the fibers are then hot stretched to about four times their initial length. This helps reduce the width. The fiber is then spun onto cones or is compressed into small folds and cut into specific lengths, creating an accordion-like texture. If these fibers are durable, they are spun into thick yarn.

The finished product is polyester. This polyester can now be dyed and knit into pieces of cloth. To attain a fluffier, fleece-like texture, the knit material is pushed through a napper, a machine that runs bristles along cloth to raise the level of the fabric, making it fuzzier.

However, this process uses a large amount of heat and consumes a lot of energy. Using the principles of green chemistry, we could use up less energy but still create the same quality polyester.

Another downside to polyester is that it may be durable and warm, but it has no breathability, and the chemicals aren’t made for constant skin contact. These chemicals could cause various problems in sensitive skin, including severe rashes. The process in which polyester is made is extremely harmful for the environment. On top of all the added chemicals, polyester is the most polluting fabrics. Polyester breaks down into microplastics, which can’t be broken down further. This pollutes the earth. If microplastics get into animals, they could harm or even kill them. Instead of using synthetic materials, we could use cotton or other natural materials that are less damaging to the environment.

In brief, polyester is a good material to keep people warm, but the process of synthesizing it is harmful for the environment.

About the Author

Shreya Virunchipuram is an eighth grader from Fremont, CA, is interested in engineering and environmental stability.